產品介紹 PRODUCTS

LPT+ Sx

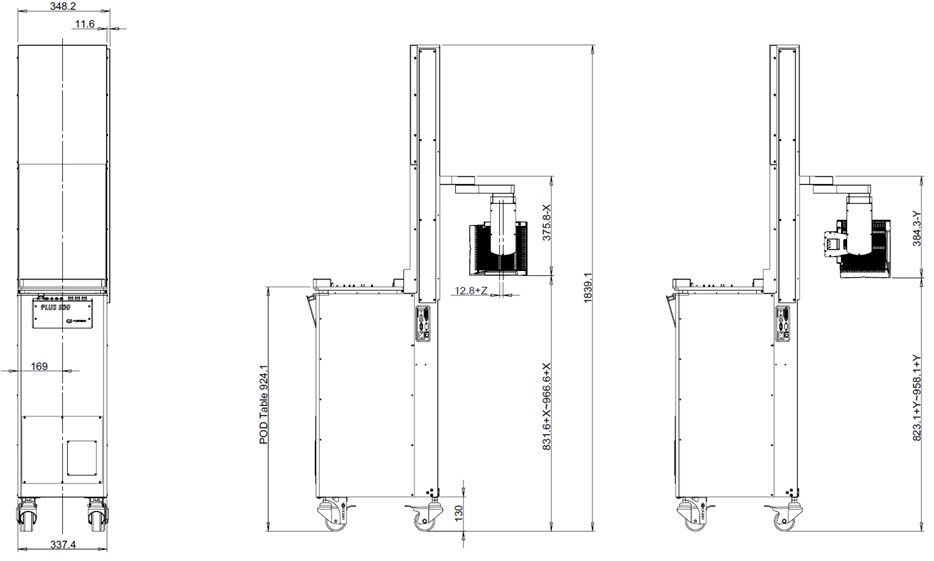

With a total footprint not much larger than a SMIF pod, the LPT+ Sx is easy to integrate with AGV system and into small areas.

A programmable robotic arm and end effector that can tilts 90˚ and does extra 85mm lateral movement supporta wide variety of process tools that cannot be used with standard models.

Features

- Less than 90-second cycle time maximizes production

- Small footprint saves valuable FAB floor-space

- Tilt and Slide end effector meets special customer requirements

- Adjustable loading height provides ergonomic efficiency

- Built-in mini-environment and clean airflow system maintain Class 1 cleanliness

- CE and S2S8 certification

Simple to Maintain

All LPT+ models feature a variety of tool interface options: diamond-pin interface plate with quick-release latches and stand-alone floor mount enabling reconnection to and from virtually any process tool within 15 minutes or less. Considering that during ramp-up a pod loader may be disconnected and reconnected as often as twice a day to adjust the process tooling, this feature significantly reduces downtime and simplifies preventive maintenance.

Safe and Reliable

A patented, built-in mini-environment and airflow control system help protect wafers from contamination, while the robot is transferring pod between SMIF pods and tool stages.

With many fail-safe features including pod present sensor, wafer protrusion sensor,cassette overload sensors, constant toque dc stepper motors (with encoder feedbacks) for accurate and reliable motion controls, the LPT+ Sx-X is the best choice for both OEMs and system integrators.

Outstanding Support

Installation, on-site training, worldwide supports and variety choices of economical long-term maintenance contracts are available from Fortrend.

Established in 1979, Fortrend's expertise in robotics, mechanics and software provide the optimum solution for semiconductor manufacturers who are driven to improve yield, increase throughput and reduce costs.

Type Information

LPT+ Sx-X

①-②

①: Standard body with Slider Option –View from operator side

SR –Right Hand (Slider moves to left)

SL –Left Hand (Slider moves to right)

②: Utility Side – View from operator side

R – Right Hand Side

L – Left Hand Side

Class 1 Cleanliness

<0.1 PWP @ 0.2 μm or greater size particles

<90-second cycle time (with tilt and lateral movements)

2,000 hours MTBF

Latches unlock the SMIF pod, Mini-environment risesand lifts the SMIF pod cover while maintaining Class 1 cleanliness inside SMIF pod. Robot arm picks up cassette andplaces it on to process tool stage. Process is reversed forunloading.

Cassette present and wafer protrusion sensors

Cassette overload sensor

Static-dissipative plastic windows

Fail-safe cassette gripper

Built-in diagnostics

PIO safety interlocks and programmable macros

Power failure recovery system automatically returns

cassette to home position

Parallel I/0 (SEMI E23-96) 8 inputs / 8 outputs

EIA-RS232(SECS I/II)

50x35x184cm(20x13.7x72.4 inches)

90cm standard load height, adjustable

93kg(206 lbs) total weight

100~240v AC standard, single-phase, 50/60Hz, 3 amps

IR Link/RFID System/IR-RF combo(options)

Specifications subject to change without notice